Starch mogul plant

- Price

- US $820000

- Model

- DR-II 8000S

- MOQ

- 1 piece

Item specifics

- Condition

- New

- Application

- Candy

- Voltage

- 380v

- Power(W)

- 95kw

- Weight

- 10000

- Certification

- ce

- Warranty

- 1 year

- After-sales Service Provided

- Engineers available to service machinery overseas

- machine

- gummy

Review

Description

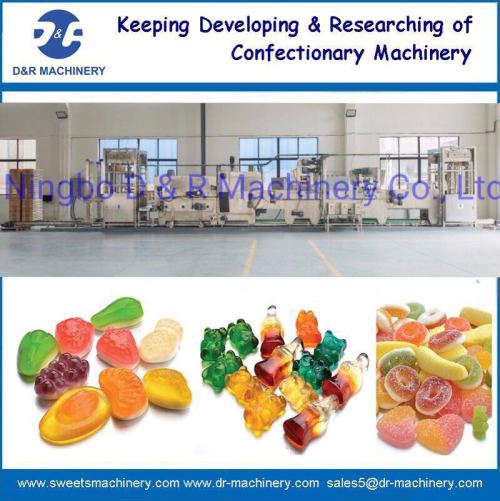

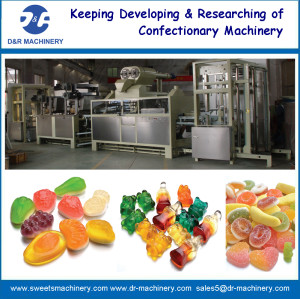

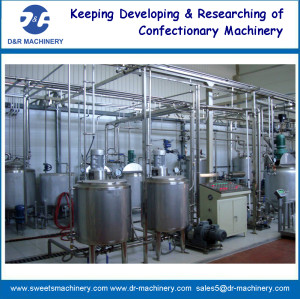

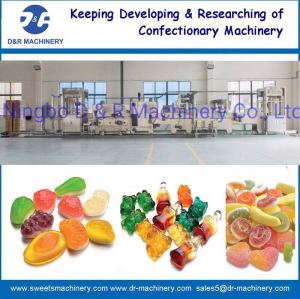

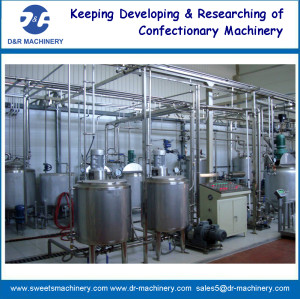

STARCH MOGUL PLANT

This plant exclusively producing the jelly candy. With high quality, Easy operation, Working credibility and speed stabilization full plat including cooking system. Pouring system, Candy convey system, Powder manager and power recycle system, The candy shape selected by customer, We will let customer get the best Production effect and bigest production capacity through our speciality design our plant suit for producing jelly candy. Glutin soft candy. Pectic soft candy. And contton candy and so on.

Production capacity | 6000kg/8h(Depends on the shape of candy) |

Power | 95KW(Depends on the machine type) |

Steam 7-8 bar | 850kg/h |

Constringent air 0.6mpa | 400 m3/h |

4 Degree cooling flux | 315kg/min(no this item if cooling by air or water) |

D&R mogul plant especially producing gummy candies.With high quality,easy operation,working reliable,with high output.The whole plant include kitchen system,mogul plant ,starch conditioning system,starch collecting and recycle system,product finishing and ancillary machinery.The plant suits for producing gelatin base candies,foamed candies and so on.What ever your production requirements,D&R has the right solution.We offer different types of depositors to meet to your needs for flexibility and speed.We offer the depositing type with swing,one shot,servo driven for centre filled gummies and stripe gummies.

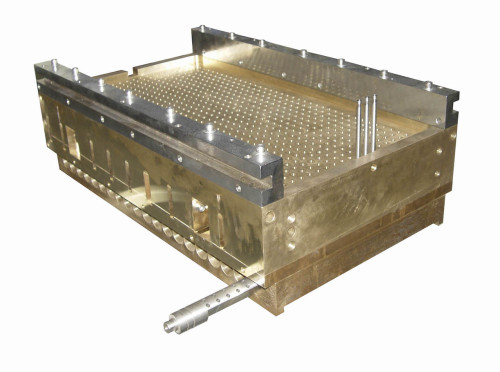

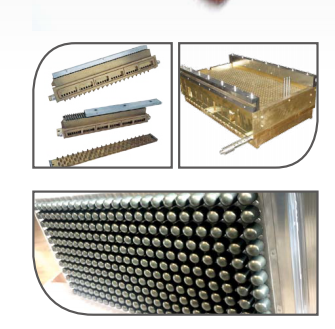

Pump casting is made of glass hard copper alloy, wear-resisting and corrosion-resistant. Its dimensional precision is ensured by digital control process center.There are many models to choose from,its diameter ranging from 9 to 20,with 720 ples pistons, hole 192, and hole 160 in a line. There is also pump casting with filling, and holes on it are arranged in a reasonable way, meeting customers' demands for diversity.

Molding is made according to customer's requirements, and its arrangement is designed by engineers to yield the best effects.Molding is die cast with copper alloy,with its surface sprayed with anti sticking no powder,The molding frame is easy and convenient to be disassembled.

Notes:

1. CAPACITY OF MOGUL PLANT

The capacity of Mogul Plant is 800-1000kgs/hour

2. DELIVERY OF MOGUL PLANT

The delivery time of Mogul Plant is 6 months